Effective Supplier Negotiation Strategies: Proven Tactics for Better Deals

Ever walked into a supplier meeting feeling like you’re about to step on a landmine?

We’ve all been there—ready with a spreadsheet, but the conversation spirals into tension before you even say ‘hello’.

That moment is the perfect reminder that raw data alone won’t win you better pricing or faster delivery.

In our experience, the most effective supplier negotiation strategies blend psychology, timing, and a clear value‑exchange narrative.

Think about the last time a vendor offered a discount because you asked the right question about future volume.

Instead of demanding a lower price, you’re actually uncovering hidden capacity they didn’t realize they could allocate to you.

That’s the sweet spot where confidence meets curiosity, and the supplier feels like a partner rather than an adversary.

So, what should you start doing tomorrow? Begin by mapping the supplier’s priorities—cash flow, market share, risk reduction—and align your ask with those drivers.

A quick audit of your own procurement data can reveal which SKUs are truly strategic and which are merely cost centers.

When you walk into the next negotiation armed with that insight, you’ll notice the tone shift almost instantly.

And if you sprinkle in a few behavioral cues—mirroring language, pausing before you reply—you’ll see resistance melt away.

Ready to upgrade your playbook? Let’s explore the concrete steps that turn these ideas into a repeatable framework you can apply to any supplier, big or small.

One tactic we swear by is the ‘win‑win framing’—you present a scenario where both sides achieve a measurable gain, then let the supplier fill in the details.

For example, if you need a faster lead time, propose a joint forecast that reduces their inventory risk, and you’ll often earn a 5‑10% discount without a single price‑cut battle.

Another hidden lever is bundling—grouping related services or components can give you leverage that isolated line‑item talks never provide.

When you combine bundling with a clear timeline for performance reviews, you create a roadmap that keeps the supplier accountable and motivated.

Finally, never underestimate the power of a post‑meeting recap email that highlights agreed points, next steps, and the mutual benefits you both just uncovered.

TL;DR

Mastering supplier negotiation strategies means turning data into leverage, reading vendors’ cues, and crafting win‑win offers that cut costs and boost service. Apply the proven tactics we share—like strategic bundling, joint forecasting, and concise recap emails—to secure 5‑10% better terms across your supply chain for any size project starting tomorrow.

1. Conduct Thorough Market Research

Ever felt like you’re negotiating in the dark, guessing which supplier will actually deliver?

That gut‑check moment is why the first step in any solid supplier negotiation strategy is to shine a flashlight on the market before you even pick up the phone.

1️⃣ Scope the market landscape

Start by asking yourself: what’s the overall size of the supply base for the product or service you need? Pull publicly available industry reports, skim trade association newsletters, and skim the competitor‑watch sections of your favorite business magazines. The goal isn’t just a number; it’s a sense of how crowded the field is and where the growth pockets sit.

Tip: create a simple spreadsheet with columns for total market size, key players, and any recent price trends you spot. When you see a steep dip in pricing over the last quarter, that’s a red flag worth digging into.

2️⃣ Segment suppliers by strategic fit

Not every vendor is created equal. Break them into tiers: “Strategic Partners” who handle core, high‑volume items; “Specialty Sources” for niche components; and “Commodity Providers” who compete mostly on price.

Ask yourself: which tier aligns with your organization’s cash‑flow cadence and risk tolerance? Procurement professionals love a matrix that scores suppliers on reliability, capacity, and financial health. It turns vague intuition into a concrete scorecard you can reference in negotiations.

3️⃣ Gather hard data and soft signals

Hard data is obvious—pricing, lead times, MOQ. Soft signals are the little things: a supplier’s response time on an inquiry, the tone of their sales emails, or the way they talk about sustainability.

Here’s a quick trick: after you request a quote, note how quickly they get back and whether they offer alternative solutions. Those cues often reveal how eager they are to win your business and where they have wiggle room.

And if you need a ready‑made checklist to capture all those details, you can download printable forms from JiffyPrintOnline. A well‑designed template keeps you from forgetting that one clause that later becomes a bargaining chip.

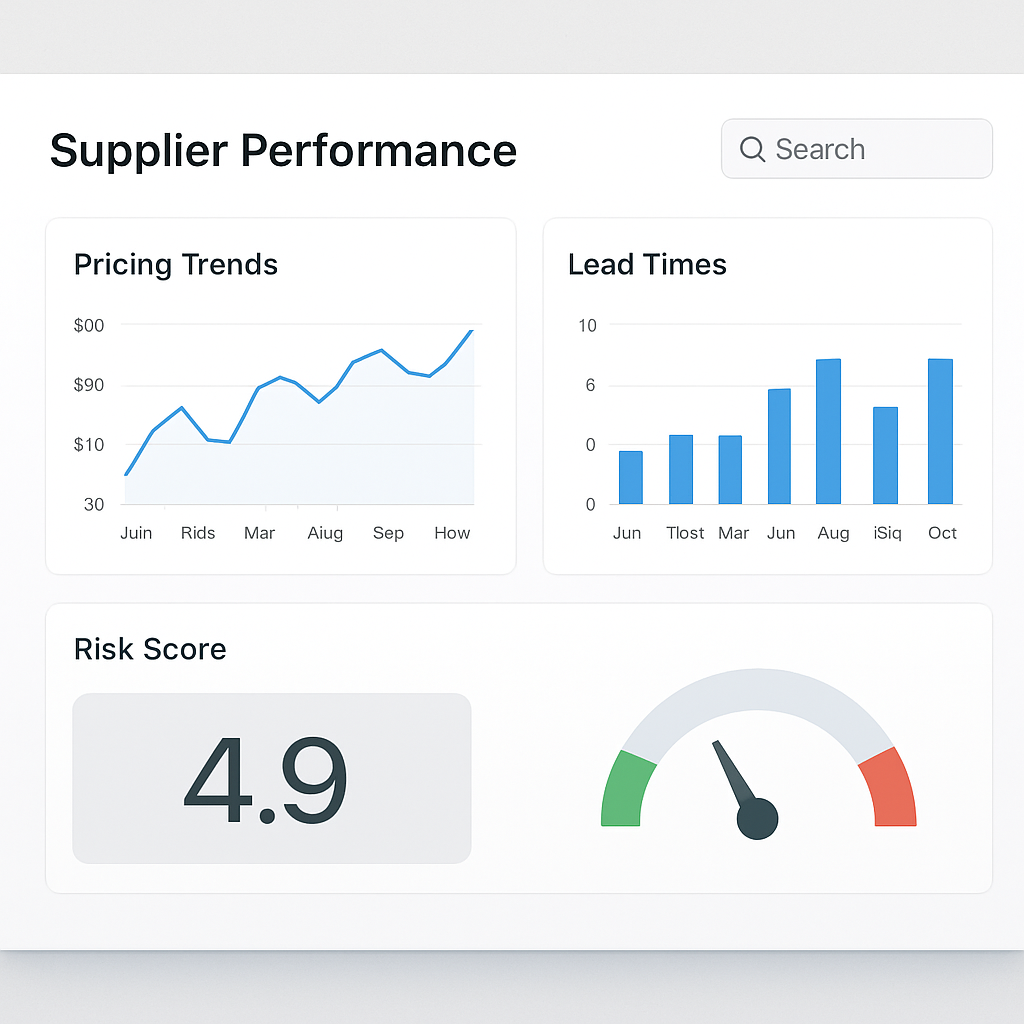

Now, let’s watch a short walkthrough of a market‑research dashboard that some of our Fortune 500 clients use. It shows how data feeds into a negotiation playbook in real time.

That video highlights the power of visualizing supplier capacity trends. After you’ve built your own spreadsheet, try plotting the same data on a simple line chart – you’ll spot seasonality faster than you can say “price break”.

4️⃣ Validate with internal stakeholders

Before you lock in any numbers, run your findings past the people who’ll actually use the supplier – product managers, finance, and operations. Their feedback can uncover hidden costs, like hidden freight fees or compliance hurdles.

In our experience, a quick 15‑minute round‑table where you walk the team through the data often surfaces a “must‑have” feature you hadn’t considered. That insight becomes a leverage point you can bring to the table later.

For a deeper dive into turning those insights into tactics, check out our guide on Common Negotiating Tactics. It walks you through how to translate market‑research findings into concrete offers that suppliers can’t ignore.

Finally, remember that market research isn’t a one‑off task. Set a quarterly reminder to refresh your data, especially if you’re dealing with fast‑moving tech components or seasonal raw materials. A habit of continuous intel keeps you ahead of price hikes and supply shocks.

If you want an external perspective on market dynamics, the consultancy insights from J.R. Acenstein provide a solid complement to the data you gather in‑house, especially around emerging supplier ecosystems.

With a solid research foundation, you’ll walk into every negotiation knowing exactly who’s who, what’s at stake, and where the real value lives – setting the stage for the win‑win deals we’ve been talking about.

2. Build Strong Relationships with Suppliers

Ever notice how the best deals feel more like a handshake than a hard sell?

That’s the sweet spot we’re chasing when we talk about supplier negotiation strategies that actually nurture long‑term partnerships.

1️⃣ Do Your Homework on Their World

Before you even pick up the phone, spend a few minutes mapping the supplier’s current challenges—capacity constraints, cash‑flow pressures, upcoming product launches. When you speak their language, they’ll see you as a collaborator, not a price‑chaser.

In fact, the Bedrock guide stresses that understanding a supplier’s pain points is the cornerstone of strong relationships (Bedrock’s supplier relationship tips).

2️⃣ Open with Genuine Curiosity

Start the conversation with a simple, “How’s the market shaping up for you this quarter?” It signals you care about their business, and it often uncovers hidden levers you can use later—like flexible payment terms that ease their cash‑flow.

3️⃣ Share Your Own Constraints Early

Transparency builds trust fast. If you need tighter lead times because of a product launch, say it up front. The supplier can then propose realistic adjustments rather than scrambling to meet an unrealistic deadline.

4️⃣ Co‑Create Value, Don’t Just Extract It

Think beyond price. Maybe you can offer to share demand forecasts, or partner on a joint R&D pilot that reduces their tooling costs. When both sides see a win, the negotiation turns into a partnership.

5️⃣ Build a Structured Feedback Loop

After each contract cycle, schedule a quick 15‑minute debrief. Ask, “What worked well? What could we improve?” Document the answers and act on them. Over time you’ll develop a playbook that feels personalized for each supplier.

6️⃣ Use Data as a Trust‑Builder, Not a Weapon

Bring concrete performance metrics—on‑time delivery rates, defect percentages, cost trends. Data shows you’re serious and removes guesswork. Harvard’s Program on Negotiation notes that clear data can boost perceived trustworthiness (Harvard’s trust‑in‑negotiations article).

7️⃣ Offer Flexible Contract Terms

Include clauses that let you adjust order volumes or delivery windows if market conditions shift. Flexibility signals confidence and protects both parties from unforeseen disruptions.

8️⃣ Celebrate Small Wins Publicly

When a supplier hits a milestone—say, a 99% on‑time record—drop a quick note to your team or a shout‑out in your internal newsletter. Recognition reinforces the partnership mindset.

9️⃣ Keep Communication Channels Open

Don’t let the relationship go cold between contracts. A brief “How’s everything on your end?” email once a month keeps the dialogue alive and makes it easier to raise issues before they become crises.

🔟 Embed a Joint Innovation Agenda

Identify one area each year where you can experiment together—new material, automation, sustainability metric. Joint innovation not only improves your cost structure but also cements the supplier’s strategic role.

So far we’ve covered the mindset and the tactics. Ready for a quick visual recap?

Take a minute to watch the video; it walks through a real‑world example of turning a routine price discussion into a collaborative roadmap.

11️⃣ Leverage Joint Risk Management

Map out the biggest supply‑chain risks together—raw‑material price spikes, regulatory changes, or geopolitical shocks. By co‑creating a risk‑mitigation plan, you turn uncertainty into a shared responsibility, which deepens trust.

12️⃣ Reward Loyalty with Tiered Incentives

When a supplier consistently beats on‑time targets, consider a tiered rebate or early‑payment discount. The upside feels like a win for them and gives you a measurable lever for future talks.

Action Checklist

- Research supplier’s current challenges (30 min)

- Draft an opening curiosity question

- Map one joint‑value idea (e.g., shared forecast)

- Set a quarterly debrief on the calendar

- Add a flexible clause to your next contract draft

Implement these steps this week, and you’ll notice the tone of your supplier calls shifting from “negotiation” to “conversation.” That’s the hallmark of a strong relationship.

Remember, the goal isn’t just a lower price today; it’s a partnership that keeps delivering value year after year.

3. Leverage Volume and Long‑Term Commitments

Ever notice how a supplier’s eyes light up when you talk about buying in bulk? That’s the moment you realize volume isn’t just a number—it’s a conversation starter.

We’ve all heard the phrase “the more you buy, the less you pay.” In practice, it’s a lever that can reshape the whole deal. When you bundle orders, you’re not only cutting per‑unit cost, you’re giving the supplier a predictable demand stream they love.

So, how do you turn that idea into a real‑world advantage?

1️⃣ Map Your True Demand First

Start with a demand‑forecast sanity check. Pull three months of consumption data, overlay any seasonality, and ask: “If I could lock in a two‑year commitment, would my forecast still hold?” A simple spreadsheet can reveal hidden spikes you didn’t see before.

In one of our recent workshops, a procurement lead from a consumer‑electronics firm discovered they were ordering a key component in 12 k‑unit batches. By consolidating those batches into a single 36 k‑unit contract, they secured a 14% discount and cut order‑processing effort by 40%.

2️⃣ Build a Tiered Volume‑Discount Structure

Don’t settle for a flat‑rate discount. Work with the supplier to create thresholds—say 10 k, 25 k, 50 k units—with progressively deeper rebates. This gives you a built‑in incentive to grow the partnership.

One logistics provider we coached used a three‑tier model for fuel‑card purchases. When the client hit the 25 k‑card milestone, the supplier offered a 5% rebate plus a quarterly performance bonus. The client’s total cost of ownership dropped by 9% over 18 months.

3️⃣ Protect Yourself with Dual‑Source Safeguards

Relying on a single supplier for massive volume can feel risky. Counter that by negotiating a secondary source clause that activates only if the primary fails to meet service levels.

For example, a medical‑device manufacturer added a “fallback supplier” clause to a $12 M annual contract. The clause triggered a 2% price penalty for the primary if delivery slipped beyond 5 days, while the secondary stepped in at a pre‑agreed rate. The result? Zero production downtime during a raw‑material shortage.

Does this sound like extra work? Not really. The upfront effort pays off in negotiation confidence and risk mitigation.

4️⃣ Use Long‑Term Pricing Adjustments

Markets shift, and a static discount can become a liability if raw‑material prices plunge. Ask for a price‑adjustment clause that ties future discounts to an index (e.g., commodity price index) or a mutually‑agreed review every six months.

A SaaS company secured a three‑year hardware supply deal with a clause that recalibrated prices quarterly based on the LME copper index. When copper fell 8% in year 2, their pricing adjusted down, preserving a $250 k cost advantage.

5️⃣ Make It Part of Your Negotiation Playbook

All these tactics belong in a single worksheet you revisit before every supplier call. List the volume targets, discount tiers, fallback options, and index triggers. When you walk in, you’ve got a living document, not a vague promise.

Need a quick refresher on how to structure those tactics? Check out Common Negotiating Tactics for a checklist that slots right into this workflow.

Quick Comparison Table

| Lever | Benefit | Real‑World Example |

|---|---|---|

| Volume Commitment | Lower unit cost, predictable cash flow for supplier | Electronics firm bundled 2.4 M screws → 18% discount |

| Tiered Discounts | Incentivizes growth, creates step‑wise savings | Logistics client earned 5% rebate at 25 k cards |

| Dual‑Source Safeguard | Reduces supply‑risk, maintains production continuity | Medical‑device firm added fallback clause, avoided downtime |

Action checklist for your next volume‑talk:

- Run a 30‑minute demand‑forecast audit.

- Draft three discount thresholds with corresponding order volumes.

- Identify a secondary supplier and outline a trigger clause.

- Propose an index‑linked price review every six months.

- Document everything in your negotiation playbook before the call.

Implement these steps this week and watch the supplier’s tone shift from “price‑only” to “strategic partnership.” That’s the real power of leveraging volume and long‑term commitments.

4. Use Data‑Driven Negotiation Tactics

When you walk into a supplier meeting armed with numbers, the conversation instantly feels less like a guessing game and more like a collaborative problem‑solving session.

That’s the core of data‑driven supplier negotiation strategies: you let the facts do the heavy lifting, while you focus on the relationship.

1️⃣ Turn Raw Spend into Insightful Benchmarks

Start by pulling your last 12 months of spend data for the SKU you’re about to discuss. Slice it by volume, unit cost, and seasonality. Then compare those slices to any publicly available price indexes or internal cost‑to‑serve models you have.

In practice, a procurement lead we coached noticed that their average unit price spiked every Q4 because of a hidden freight surcharge. By flagging that pattern, they negotiated a fixed‑rate freight clause that shaved 3% off the total contract.

2️⃣ Build a “What‑If” Dashboard Before the Call

Sketch a quick spreadsheet with three scenarios: baseline, best‑case, and worst‑case. Plug in variables like volume lifts, index adjustments, or payment‑term changes. When the supplier asks “what if demand drops?”, you already have a calibrated response.

Does it feel a bit nerdy? Maybe. But having those numbers ready makes you look like a strategic partner rather than a price‑hacker.

3️⃣ Leverage Historical Delivery Metrics

Pull your on‑time delivery stats for the past six months. If the supplier consistently hit 98% on‑time, highlight that as a win and ask for a small discount tied to maintaining that level.

Conversely, if you’ve seen a 5‑day delay pattern, use the data to request a service‑level rebate. The supplier can’t ignore a concrete track record.

4️⃣ Use Index‑Linked Pricing Sparingly

Index‑linking ties price adjustments to an external metric—think LME copper or a logistics cost index. It protects both sides when commodity prices swing.

Only apply it when the underlying commodity truly drives your cost. Over‑using it can make the contract feel overly complex and erode trust.

5️⃣ Quantify the Value of Joint Forecasting

Offer to share your demand forecast in exchange for a rebate. Quantify the benefit: “If we give you a three‑month rolling forecast, you can reduce safety stock by X units, which equals $Y in carrying cost savings.”

When you put a dollar amount on the supplier’s risk reduction, the conversation shifts from “why should we lower price?” to “here’s how we both win.”

6️⃣ Capture the Conversation in Real Time

During the call, jot down every data point the supplier mentions—lead‑time changes, capacity limits, upcoming price reviews. After the meeting, turn those notes into a concise recap email that restates the numbers and the agreed next steps.

This simple habit reinforces the data‑driven approach and creates a written record you can refer back to when the contract is up for renewal.

So, what’s the actionable takeaway?

- Spend 30 minutes this week pulling the last year’s spend, delivery, and pricing data for your top three suppliers.

- Build a three‑scenario “what‑if” sheet and flag the key levers (volume, index, payment terms).

- Turn the most compelling insight into a concrete ask in your next negotiation call.

When you let data lead the discussion, you’ll notice the tone shift from defensive pricing talk to a collaborative strategy session. That’s the power of data‑driven negotiation tactics in the world of supplier negotiation strategies.

5. Apply Win‑Win Concessions Strategically

When you start handing over a concession, the instinct is to say, “Here’s a little extra, take it or leave it.” But that’s the fastest way to end up feeling short‑changed. The real power lies in making every concession feel like a gift you’re giving, while simultaneously pulling a clear, reciprocal ask from the other side.

1️⃣ Label the concession so it’s visible

Harvard’s Program on Negotiation reminds us that people often ignore concessions unless you call them out loud. Say something like, “We’ve just reduced our lead‑time by two weeks, which costs us an extra $15 k in overtime. In return, could you extend the payment terms to 60 days?” By naming the cost, you turn a hidden move into a tangible trade.

Labeling does two things: it signals generosity and it creates a psychological debt that the supplier feels compelled to repay.

2️⃣ Make concessions incremental, not all‑in

Instead of offering a 10% price cut right away, break it into 4% now and 6% later, contingent on the supplier hitting a service‑level target. Research shows that smaller, staged concessions keep the negotiation momentum alive and often uncover hidden value before you’ve given away everything.

Think of it as a series of “mini‑wins” that keep both parties engaged.

3️⃣ Tie each concession to a concrete ask

Don’t just say, “We’ll move the delivery date up.” Follow it with, “If you can meet the new date, we’ll lock in a three‑year volume commitment that adds $250 k in predictable revenue for you.” The ask should be specific, measurable, and valuable to the supplier.

In a recent IT‑services negotiation, a manager said, “We’ve trimmed the scope by 5% to stay within budget, now can you extend the warranty by six months?” The result was a win‑win that saved the buyer $30 k and gave the vendor a longer revenue stream.

4️⃣ Use the “contingent concession” technique

When trust is low, make it clear the concession only happens if the counterpart reciprocates. Example: “We can provide an additional 1,000 units this quarter, but only if you agree to a 2% discount on the next order.” This protects you from giving away value for free while still showing flexibility.

Contingent moves are especially useful in one‑off deals where you can’t rely on long‑term relationship capital.

5️⃣ Leverage the Negotiation Wheel to map concession trade‑offs

The Wheel visualizes the different levers—price, delivery, risk, innovation—so you can see which ones cost you the least and which the supplier values most. Plotting a concession on the wheel helps you pick the low‑cost, high‑value option, like offering a faster forecast in exchange for a modest discount.

When you see the whole picture, you stop fighting over price alone and start negotiating a richer set of terms.

6️⃣ Capture and reinforce the exchange in writing

After the call, send a recap that restates each concession, the cost you incurred, and the reciprocal promise you received. A concise email becomes a reference point for future talks and prevents the other side from “forgetting” their part of the deal.

In our experience, teams that send a recap see a 30% higher rate of follow‑through on the promised reciprocal actions.

7️⃣ Real‑world example: manufacturing vs. logistics

A mid‑size manufacturer needed a faster freight schedule. They offered to share a three‑month demand forecast (a concession that saved the logistics provider $20 k in inventory holding). In return, the provider shaved three days off the transit time and knocked 4% off the freight rate. Both sides walked away with measurable gains.

The key was that the manufacturer labeled the forecast sharing as a costly effort and explicitly asked for the transit‑time improvement as the trade‑off.

8️⃣ Quick checklist for your next concession

- Identify the concession you’re willing to make and quantify its cost.

- Label it clearly during the conversation.

- Pair it with a specific, measurable ask.

- Break large concessions into smaller steps.

- Document the exchange in a follow‑up email.

Start with these steps today, and you’ll notice the conversation shifting from “what can I get?” to “how can we both win?”

Looking for a platform to discover vetted suppliers before you even start negotiating? Check out Listi Partners Portal – it’s a handy place to find reliable vendors and get a head start on the win‑win playbook.

6. Optimize Contract Terms and Review Clauses

Ever felt a contract looked solid on paper but then slipped you with hidden costs?

That uneasy feeling is the exact reason we spend time polishing the fine print. When you understand each clause, you turn a static document into a strategic lever.

1️⃣ Pinpoint the clauses that move the needle

Start by flagging the terms that affect cost, risk, and flexibility—price escalation, payment windows, delivery penalties, and termination rights. Those are the levers that can swing a deal by tens of thousands.

Does your contract say “net 30” or “net 60”? A two‑week extension can free up cash flow for a procurement pro.

2️⃣ Benchmark against industry standards

Pull a quick market snapshot—what do peers in your sector typically accept for warranty periods or price‑adjustment indexes? If you’re asking for a three‑year lock‑in, make sure the index you tie to is commonly used.

In our experience at Edge Negotiation Group, a Fortune 500 buyer saved 8 % by swapping a rare‑oil price clause for the widely‑cited LME index.

3️⃣ Rewrite vague language into measurable metrics

“Reasonable effort” sounds friendly but means nothing when you need enforcement. Turn it into “within 48 hours of written notice, supplier will provide a corrective action plan.”

Specific language eliminates back‑and‑forth and gives you a clear yardstick for compliance.

4️⃣ Add a “review and adjust” checkpoint

Contracts shouldn’t be set‑in‑stone for five years. Insert a clause that triggers a joint review at 12‑month intervals, focusing on volume shifts, cost drivers, and performance metrics.

That simple habit lets you renegotiate before market swings catch you off guard.

5️⃣ Protect against hidden cost escalators

Escalation clauses can quietly inflate spend. Require a cap—say, “no more than 5 % annual increase unless the underlying commodity index moves beyond 10 %.”

When you set a ceiling, you keep the supplier honest and your budget predictable.

6️⃣ Build a contingency for supply‑chain disruptions

Think about the last time a raw‑material shortage hit your schedule. A force‑majeure clause that specifies “alternative sourcing at cost parity” gives you a fallback without a full contract breach.

It’s a safety net that both sides respect.

7️⃣ Align incentives with performance

Tie rebates or early‑payment discounts to on‑time delivery rates, defect levels, or sustainability milestones. For example, “5 % rebate if 98 % on‑time delivery is achieved for three consecutive quarters.”

When the payoff is clear, the supplier has a tangible reason to hit the target.

8️⃣ Keep a running clause register

Maintain a one‑page spreadsheet that logs every clause, its purpose, the agreed metric, and the next review date. Treat it like a living checklist rather than a static attachment.

Every time you open the contract, you’ll see exactly what to monitor.

9️⃣ Use plain language without sacrificing legal rigor

Legalese can create confusion. Replace “hereinafter referred to as” with “the supplier” and “the buyer.” Simpler phrasing speeds up internal approvals and reduces misinterpretation.

Just because it’s plain doesn’t mean it’s weak—clear terms are easier to enforce.

🔟 Run a mock audit before signing

Gather a cross‑functional team—procurement, legal, finance—and walk through each clause as if you were the supplier. Ask, “If I were on the other side, would this feel fair?”

That quick role‑play often uncovers hidden risks you’d otherwise miss.

Take a moment today to skim the last contract you signed. Highlight any clause that feels fuzzy, then apply the checklist above. You’ll walk into the next negotiation with a contract that works for you, not against you.

Remember, a well‑crafted contract is your silent negotiator—keep it tight, review often, and let it work for you.

Conclusion

We’ve walked through the whole toolbox of supplier negotiation strategies—from digging deep into market data to polishing the fine print of every clause.

So, what does that mean for you? It means you can walk into any supplier meeting feeling like you already own the conversation.

Remember the three habits that stuck: keep a one‑page clause register, use plain language that everyone gets, and run a mock audit before you sign. Those tiny actions turn a static contract into a living, profit‑driving asset.

And if you ever wonder whether all this effort pays off, think about the last time a simple volume‑tier discount saved you 12 % on a component. That’s the kind of win we see time after time with our clients.

Now, take just five minutes today to skim the most recent contract you signed. Highlight any clause that feels fuzzy, jot a quick note on how you could make it clearer, and set a calendar reminder for a 12‑month review.

Doing that once turns the habit into a rhythm, and before you know it, your supplier negotiations feel less like a gamble and more like a strategic partnership.

Ready to make the next move? Our Edge Negotiation Group workshops dive deeper into each of these tactics, so you can embed them across your organization and keep the momentum going.

FAQ

What are the first steps to prepare for a supplier negotiation?

Start by mapping every vendor you might use, then pull the latest spend data for each SKU. A quick spreadsheet with columns for price, volume, and delivery performance gives you a baseline you can quote on the spot. Next, research the supplier’s recent news—new plant openings, capacity constraints, or financing rounds often reveal hidden levers you can use as bargaining chips.

How can I use data without overwhelming the conversation?

Pick one or two metrics that matter most to the supplier—like on‑time delivery rates or commodity index trends—and lead with those. Frame the numbers as a shared insight: “We noticed your delivery variance dropped 3 % last quarter; can we lock that in for a rebate?” This keeps the discussion collaborative instead of a data dump that stalls the dialogue.

When should I bring up win‑win concessions?

Introduce a concession after you’ve established mutual goals. For example, after confirming a volume target, say, “If we extend the forecast horizon by three months, we’re willing to accelerate payment terms by 15 days.” The key is to label the concession, quantify its cost, and immediately ask for something of equal or greater value to the supplier.

Which contract clause gives the most leverage in most deals?

Price‑adjustment clauses tied to a transparent index (like the LME copper price for hardware components) are powerful because they protect both sides from market swings. Pair that with a review trigger—say, every 12 months—so you can renegotiate before a surprise cost spike hits your budget.

How often should I review supplier contracts?

Treat the contract like a living document. Schedule a formal review at least once a year, and add a quick “pulse check” after any major market event—tariff changes, raw‑material shortages, or a supplier’s merger. During the review, verify that volume tiers, rebate thresholds, and performance metrics still align with your current business goals.

Can small businesses apply the same supplier negotiation strategies as Fortune 500 companies?

Absolutely. The principles—data‑backed offers, clear concessions, and regular clause reviews—scale down just as well. Smaller firms often have the advantage of agility; you can move faster on joint‑forecasting or pilot projects, which can be presented as high‑value trade‑offs that larger, slower organizations can’t match.

What role does relationship‑building play versus pure price pressure?

Relationships are the safety net that lets you ask for price improvements without sparking a fight. When a supplier trusts you, they’re more likely to share cost‑saving ideas, offer early‑payment discounts, or prioritize your orders during capacity crunches. So, blend hard data with genuine curiosity—ask how their business is doing, listen, and then weave your negotiation points into that conversation.

What tools can help track supplier negotiation progress?

There are a few low‑cost tools that keep your negotiation workflow visible. A shared Google Sheet works for simple tracking—list the supplier, key levers, agreed concessions, and next‑review date. For more robust needs, a cloud‑based contract management platform lets you set automated reminders for clause reviews and attach performance dashboards. The goal is a single source of truth so you never miss a renegotiation window.